Screen Printing

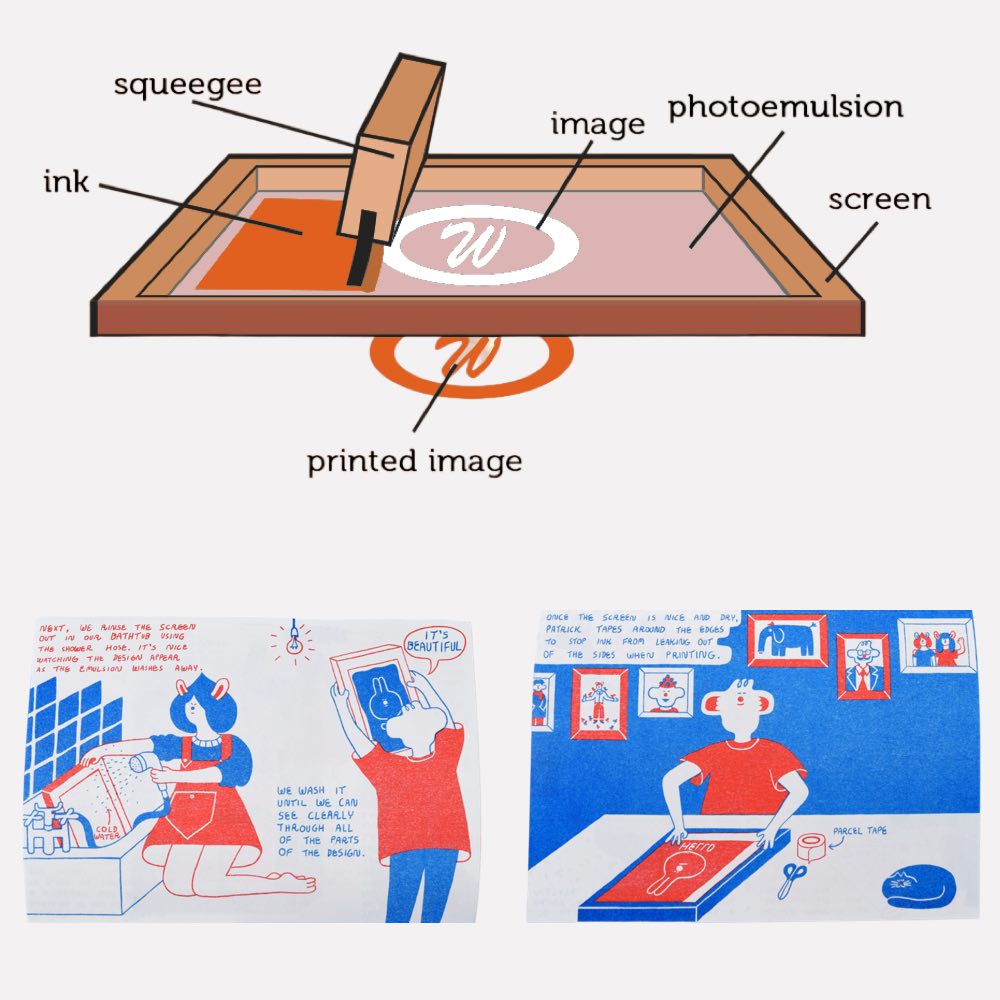

Screen printing involves transferring a design from a template onto a flat surface using a screen, ink, and a squeegee. While fabric and paper are the most common surfaces for screen printing, with specialized inks, it can also be applied to wood, metal, plastic, and even glass. The basic method includes creating a stencil on a fine mesh screen and then passing ink (or paint, in the case of artworks and posters) through it to leave the designed imprint on the underlying surface.

Application Areas

Embossing utilizes a convex template (positive template) under pressure to imprint the surface of the printed material, creating a raised, three-dimensional pattern. This process adds a tactile and visual impact to the printed material. Embossing is performed on paper with a weight of 200g and above, typically on heavyweight specialty papers with noticeable texture.

Debossing

Screen printing can be applied to flat, curved, and even irregular surfaces, showcasing great flexibility. The ink layer after printing is thick, providing a strong three-dimensional effect. The screen printing process involves simple equipment, easy operation, straightforward printing and plate-making processes, and low costs, making it highly adaptable in various applications within the printing industry.

Blind Embossing

Blind embossing utilizes a metal roller with engraved patterns that, when pressed, leaves a full-page textured pattern on the surface of the paper.

These techniques are fundamental in the printing industry for creating visually and tactilely appealing textures and patterns on printed materials.

Case Studies

CASE ONE

Accordion-folded Book

14*28 (or customized)

Screen printing