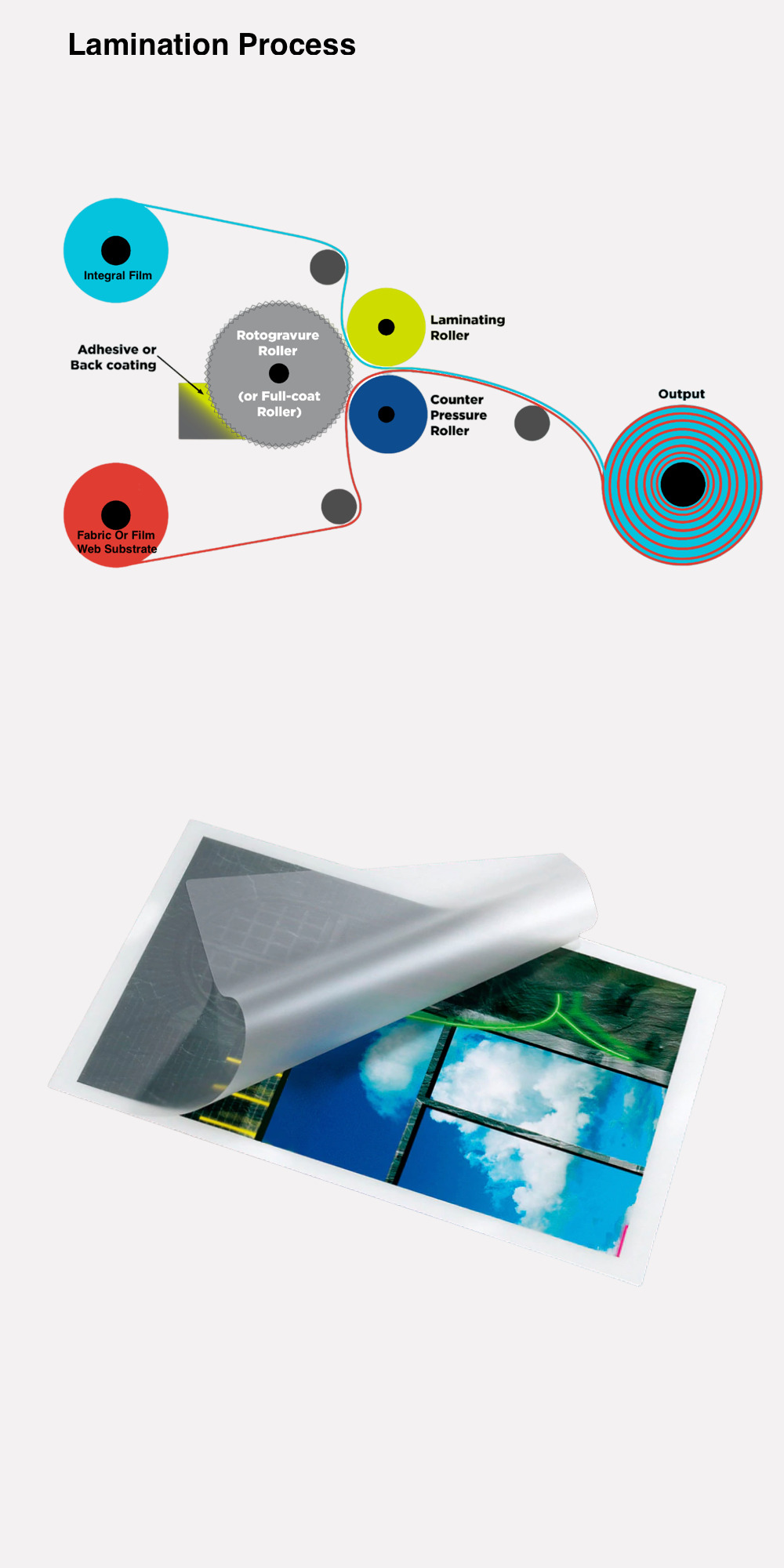

Lamination Process

The lamination process, commonly referred to as the glazing process, generally includes glossy lamination and matte lamination. Glossy lamination has a shiny appearance but is relatively less used nowadays. Matte lamination, on the other hand, imparts an elegant and high-end feel. There is also a type known as tactile lamination, providing a finer and smoother feel, though it is less prevalent due to its higher cost.

The Primary Benefits of Laminated Printing

1.Water, Smudge and Tear Resistant

2.Stability

3.Cost Effective and Time Efficient

Application Areas

Lamination is applied to various areas, including book covers, brochure covers, outer layers of packaging boxes, labels, folded sheets, and more. It is important to note that lamination is primarily suitable for coated papers, matte-coated papers, and uncoated papers with relatively smooth surfaces, whereas it may not be suitable for papers with textures like book paper or uncoated textured paper.

Case Studies

CASE ONE

Magazine —- softcover book

Size:8*10 inch (or customized)

Cover-to-cover lamination