Embossing / Debossing / Blind Embossing

Known as embossing, this process involves creating localized changes on the substrate to form patterns through pressure. It utilizes two plates, the embossing plate, and the counterplate, which are pressed together. There are two types: the cost-effective conventional etched plate and the expensive laser-engraved plate.

Embossing

Embossing utilizes a convex template (positive template) under pressure to imprint the surface of the printed material, creating a raised, three-dimensional pattern. This process adds a tactile and visual impact to the printed material. Embossing is performed on paper with a weight of 200g and above, typically on heavyweight specialty papers with noticeable texture.

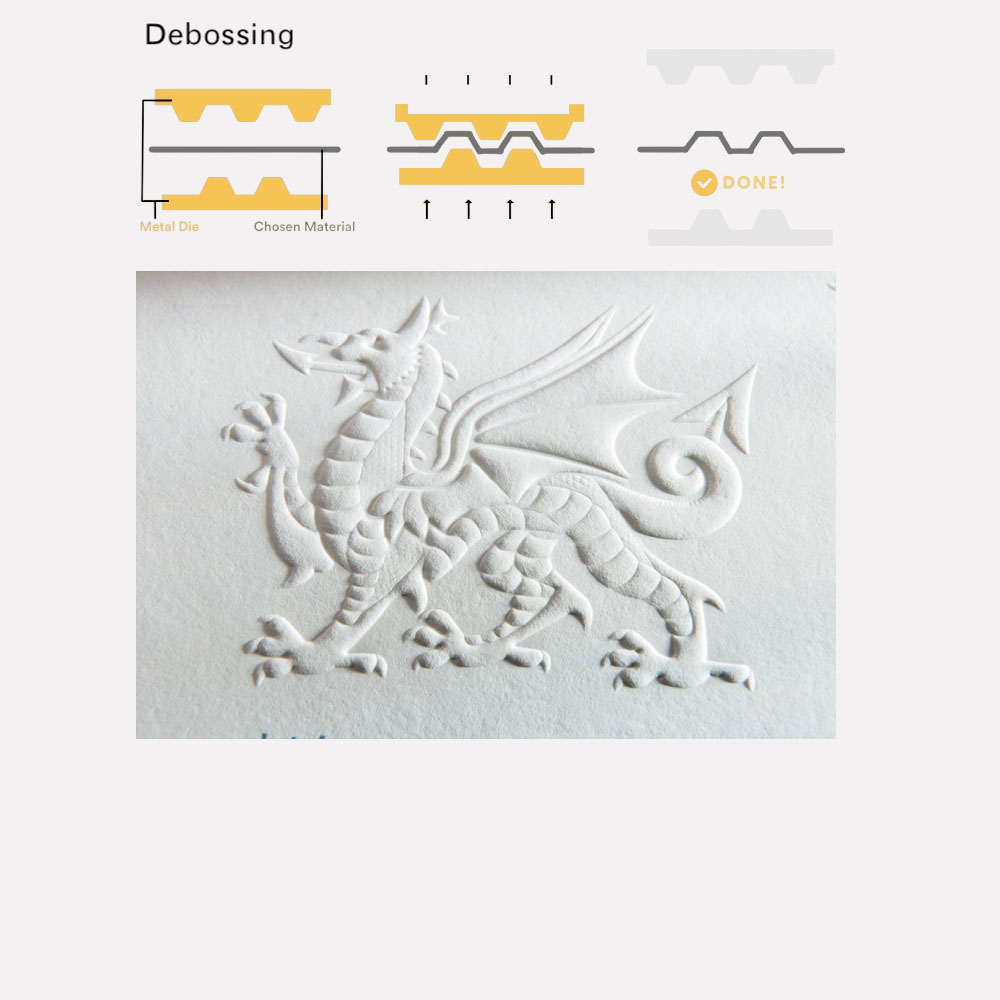

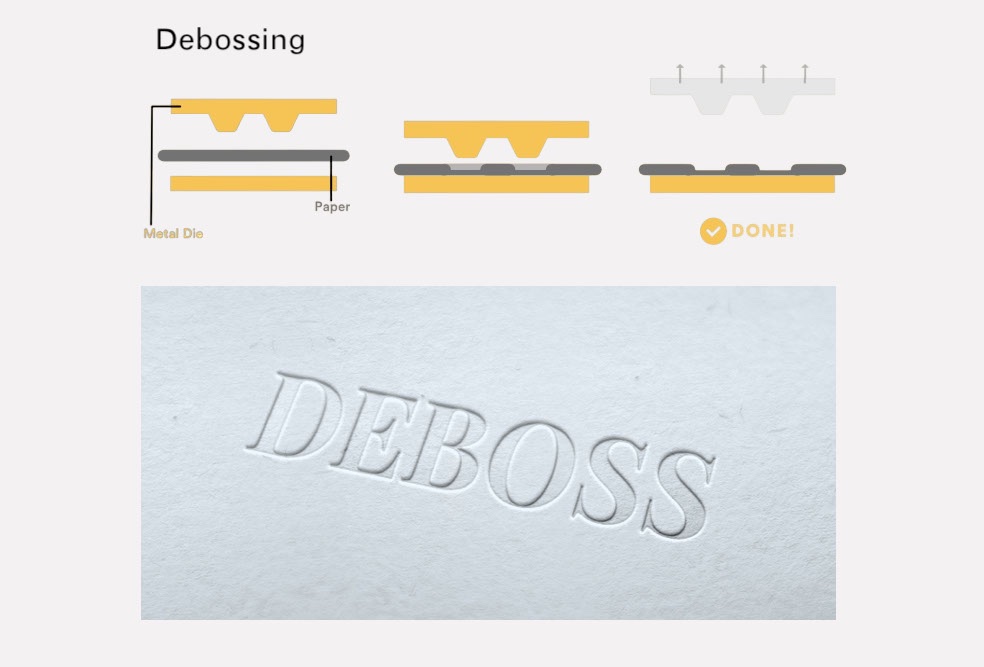

Debossing

Debossing employs a concave template (negative template) under pressure to imprint the surface of the printed material, creating a depressed, three-dimensional pattern. Similar to embossing, debossing adds a tactile and visual impact, and the paper requirements are the same. Both embossing and debossing can be combined with processes like hot stamping, spot UV, and more.

Blind Embossing

Blind embossing utilizes a metal roller with engraved patterns that, when pressed, leaves a full-page textured pattern on the surface of the paper.

These techniques are fundamental in the printing industry for creating visually and tactilely appealing textures and patterns on printed materials.

Case Studies

CASE ONE

Hardcover Debossed Linen Book

12″ x 12″ (or customized)

White debossed linen cover

CASE TWO

Real Estate Look Book

16″ x 20″

Tree branch blind embossed

Colorful printing